iAero

| E-Mail: | kolditz@match.uni-hannover.de |

| Team: | Torge Kolditz |

| Year: | 2017 |

| Funding: | DFG |

| Is Finished: | yes |

Initial situation

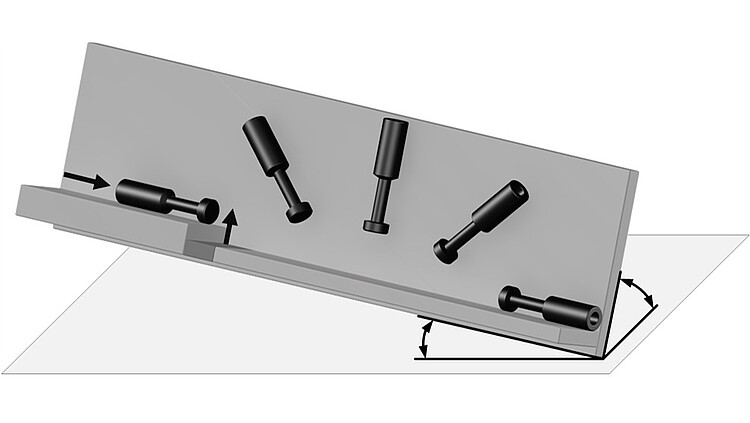

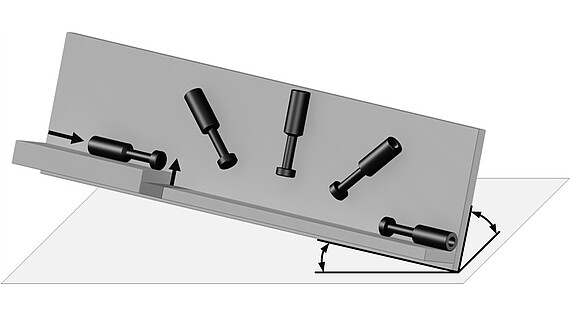

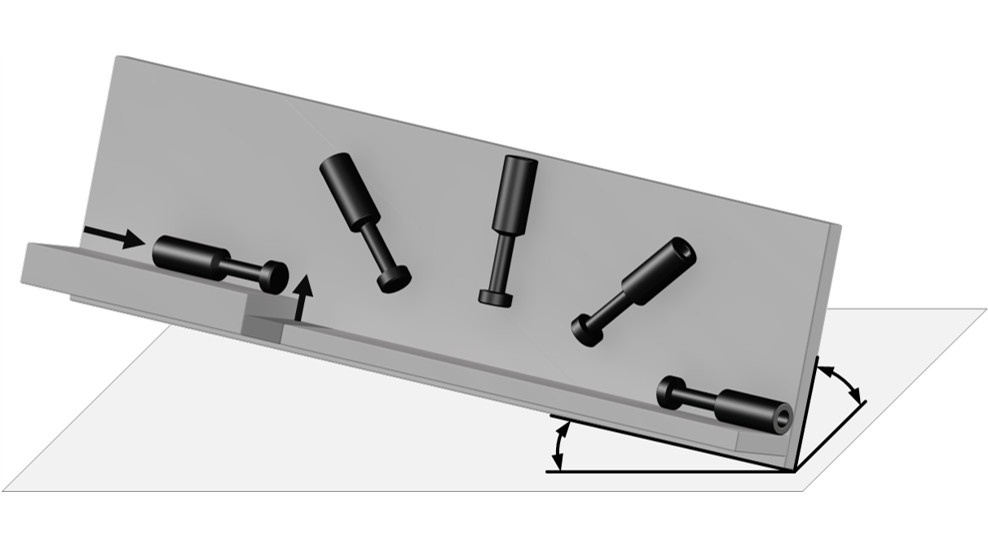

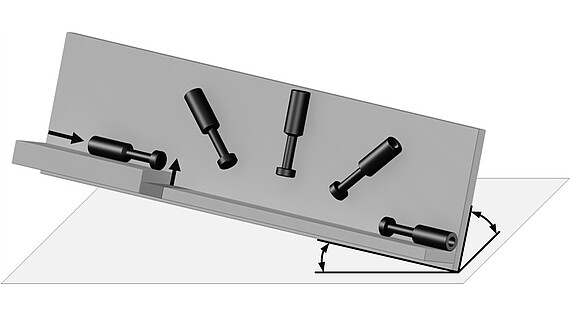

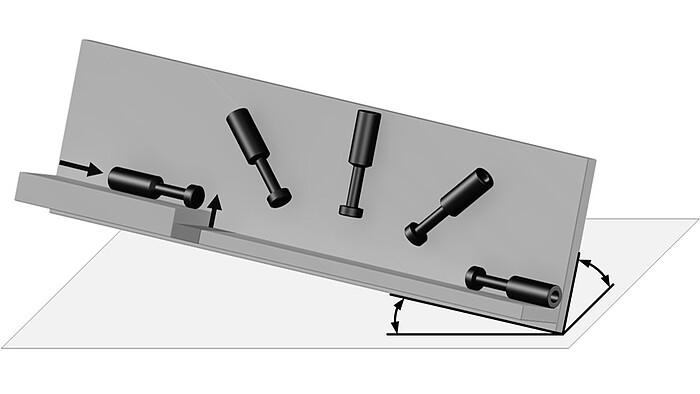

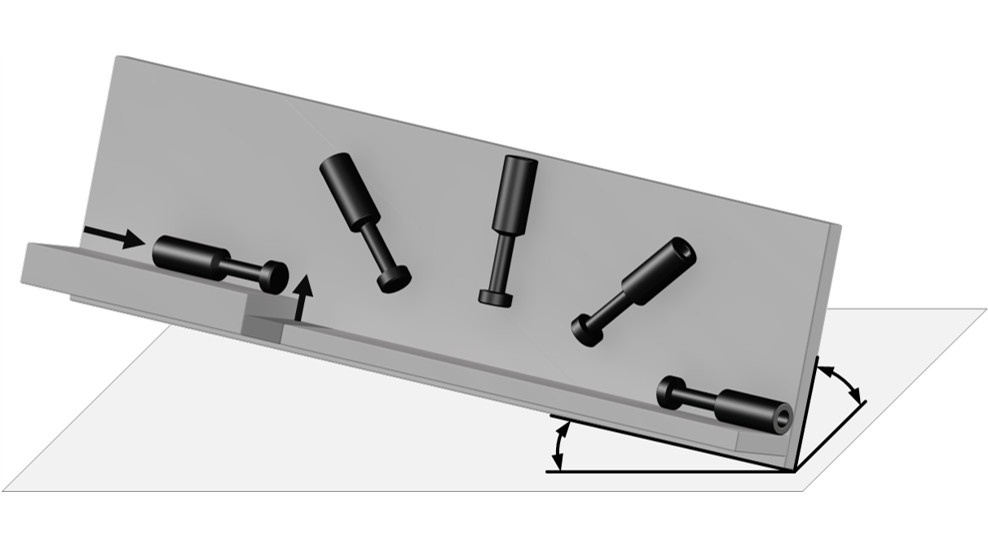

To counteract existing deficits of conventional feeding technology with regard to feeding performance, reliability and variant flexibility, an aerodynamic feeding system was developed at the IFA (Institute of Factory Installations and Logistics). This is characterized in particular by high feed rates of up to 1000 workpieces per minute and high technical availability. This feeding system can be adapted to different workpiece geometries by configuring just four system parameters. However, identifying the best possible values for these parameters was very time-consuming. Therefore, in previous research, a genetic algorithm (GA) was developed that enables the feeder to independently identify best possible values for these parameters and automatically set them using appropriate hardware. As a result, the time required to set the feeder could be significantly reduced.

Objective

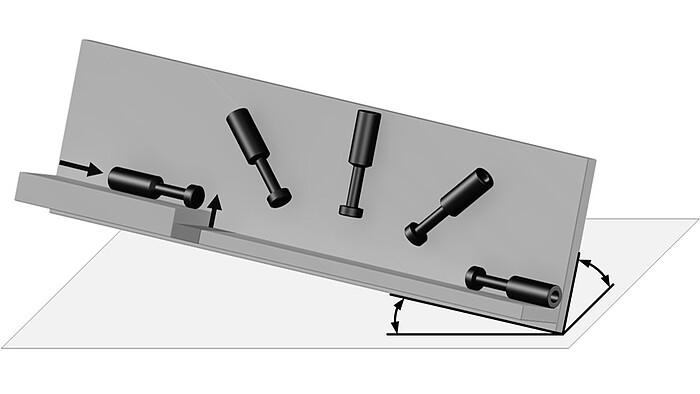

The aim is to increase the spectrum of workpieces to be fed and to further reduce the duration of the independent adjustment of the aerodynamic feeding system by further developing the simulation model and by using effective relationships between workpiece properties and the optimum design of the GA. The simulation should be generally valid with respect to limit values of workpiece properties to be defined and should be usable for the plant parameterization without the existence of simulation expertise. Furthermore, the method for dynamic adaptation to varying environmental conditions shall be extended in that the feeding performance of the aerodynamic feeding system is maximized.

Procedure

In addition to the design adaptation of the aerodynamic feeding system to increase the component spectrum, a spectrum of workpieces is to be derived based on the experimental identification of limit values for workpiece properties. Based on this, a model will be developed that can simulate the corresponding workpiece behavior during aerodynamic orientation simply by extracting relevant workpiece data from the CAD models of workpieces to be fed and implementing them in the simulation model. In this way, it should be possible to determine the optimum settings of any workpieces with the aid of the simulation, without having to carry out time-consuming and complex analyses in advance. Subsequently, the already developed method for dynamic reparameterization is to be optimized so that the feeding performance remains at the highest possible level even under changing environmental conditions.