Assembly of photonic integrated circuits

| E-Mail: | terei@match.uni-hannover.de |

| Team: | Niklas Terei |

| Year: | 2021 |

| Date: | 01-07-21 |

| Funding: | DFG (PhoenixD) |

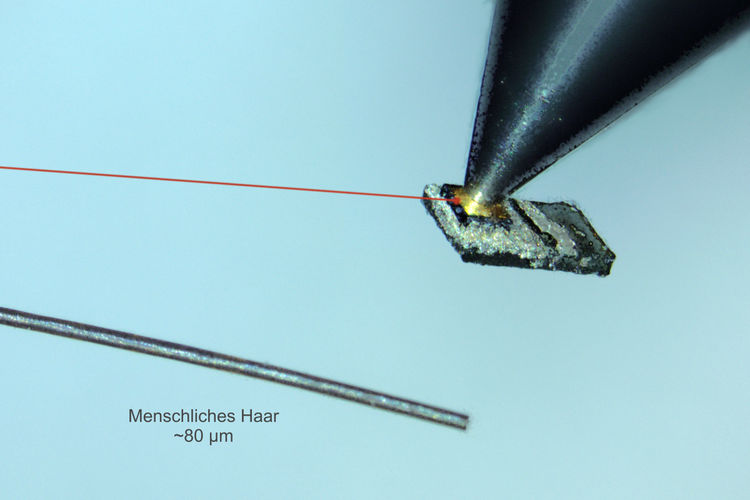

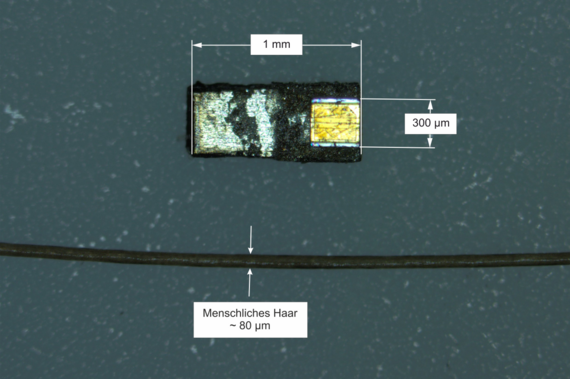

The great challenges in the assembly of photonic integrated systems lie in the handling and positioning of the optically active and passive components, which are usually only tenths of a millimetre in size. Glass fibres are especially difficult to handle due to their mechanical flexibility and the ratio of fibre diameter to length. In some cases, the light-conducting core measures only a few micrometres in diameter. Additionally, the electrical contacting of e.g. microscopic laser diodes remains a challenge.

Along with the optical quality of the individual components, the assembly tolerances are particularly decisive for the performance of optical systems. In the field of single-mode light, nanometre precision is necessary, which in practice can only be achieved by highly specialised but inflexible assembly systems. Because common image-based measuring systems reach their physical limits at these scales and to maximize optical performance, alignment is induced by time-consuming active alignment processes.

To realise efficient and reliable assembly of optical systems, the we are researching novel solutions for assembly and handling processes. In particular, adhesive bonding processes are considered, as the assembly tolerance is significantly influenced by the curing and the resulting adhesive shrinkage. Furthermore, we are working on novel gripper systems and on self-optimising processes in which process data along the entire development and production chain are used to predict process influences. For this purpose, simulation, development and production data of the optical systems developed in PhoenixD are combined in a uniform data format.

Contact: Niklas Terei

Microscope image: Size comparison of a microscopic laser diode on submount and a human hair.