Assembly and Handling Technology

Assembly and Handling

-

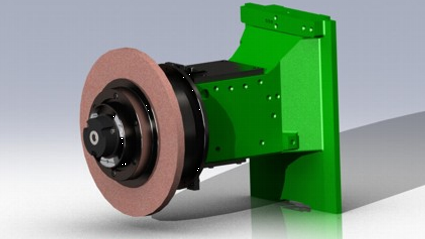

Active tool holding deviceThe research aim is to increase the productivity of machine tools with rotating tool holding devices by actively influencing the machine structure. The limiting factor for the performance of a machine tool is the dynamic and static behaviour of the structure. If machine tools are operated near their limits, undesired machine vibrations may occur. As a result, either the machining of the workpieces cannot be completed or the selected parameter values do not fully exploit the machine's performance.Team:Year: 2011Funding: DFG

![]()

![]()

-

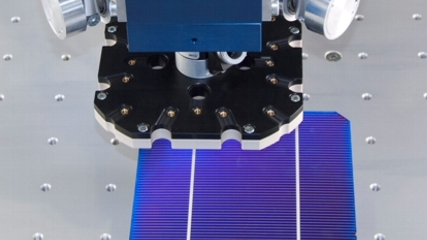

Handling of solar cellsThe aim of the project is the investigation of parallel robots for high speed handling operations of solar cells for industrial applications. Alternative parallel kinematic structures for the handling of solar cells are to be designed and the functional models of the CRC 562 for industrial tasks are to be investigated in terms of their suitability.Team:Year: 2011Funding: DFG

![]()

![]()

-

3C-PKMThe aim of the project "Development of a parallel kinematic structure for the 3C application field" is to analyse and further develop the kinematics of an ABB Flexpicker in order to meet the requirements of handling and assembly tasks in electronics assembly. To this end, the workflow of a possible development process is worked out and relevant boundary conditions and target parameters are identified.Team:Year: 2012Funding: DFG

![]()

![]()

-

ProVorPlus (Functionally integrated process technology for preassembly and component manufacturing of FRP metal hybrids)In order to increase the economic potential of fiber-reinforced plastic-based lightweight construction, the production of components with component integrated hybridization is appreciated. Different materials with different properties are combined to form a single component, which enables the functionalization (mechanical, thermal and electrical) of the individual materials.Team:Year: 2015Funding: BMBF

![]()

![]()

-

iAeroIn cooperation with the IFA (Institute of Production Systems and Logistics), an aerodynamic feeding system is to be developed further in this project, so that parts can be fed flexibly and in large quantities into a subsequent process. Based on the geometric data of the parts and a simulation model of the orientation process, the system should independently identify, adjust and apply the optimal setting parameters.Team:Year: 2017Funding: DFG

![]()

![]()

-

Methods for automation of handling processes under cryogenic conditionsIn today's industry, automation is a ubiquitous factor, even in niche applications such as cryopreservation. Manual handling of biological or toxic samples is still the norm in research facilities. Such samples are preserved and stored in so-called cryobanks at temperatures ranging from -130°C to -196°C. In cryobanks commonly used today, samples are often stored and retrieved or moved by hand with bulky protective clothing. This is necessary because there is a significant risk of injury to the worker from cold burns, as well as a risk to sample integrity from damage and heating or even temperature changes. To overcome these problems, full automation at temperatures below -130 °C is desirable. As part of the DFG-funded project "Methods for the automation of handling processes under cryogenic environmental conditions", approaches for the automation of handling processes in biobanks for cryopreservation in the temperature range below -130°C are being researched at match in cooperation with the Fraunhofer Institute for Biomedical Engineering (IBMT, Sulzbach/Saar). The challenge is to ensure the functionality of the machine components (joints, sensors, energy supply, etc.) in this temperature range in order to be able to operate the biobank at a constant low temperature level. This is intended to prevent damage to the samples due to temperature fluctuations and at the same time increase the efficiency and reproducibility of the handling processes. The basis of the automation system is a parallel robot. Its structure allows the drive technology to be decoupled from the low-temperature area and placed outside, i.e. in the warm area. In order to transfer the drive motion to the end effector platform, methods for designing passive solid-state joints are being researched at match so that they can be used at the required temperatures, e.g. using a suitable temperature control concept.Team:Year: 2017Funding: DFG

![]()

![]()

-

SafeMateThe goal of the research project SafeMate is to implement collaborative assembly systems in cross-industry applications and to develop general strategies and concepts for the introduction and design of such systems. These general strategies are to be summarised in a guideline, which is intended to provide companies with guidance in the form of action and decision-making corridors when designing collaborative assembly systems.Team:Year: 2017Funding: BMBF

![]()

![]()

-

Adaptable and Component-Protecting Disassembly in the Regeneration PathPart of the DFG-funded Collaborative Research Centre 871 "Regeneration of Complex Capital Goods" is a "component friendly and adaptable disassembly". Disassembly initiates the regeneration process of an aircraft engine. By automating the disassembly processes and identifying the process variables, it is possible to disassemble components in a way that is gentle on the components despite characteristic uncertainties.Team:Year: 2018Funding: DFG

![]()

![]()

-

Economic production of load-compatible FRP / metal compositesIn cooperation with the IFUM (Institute for Forming Technology and Forming Machines), this project aims to develop and optimize an economical production of load-bearing FRP / metal composites. Local FRP accumulations are to be arranged and fixed between two steel sheets. Subsequently, the layer structure is transferred to a two-stage press for impregnation and forming.Team:Year: 2018Funding: EFB/AiF

![]()

![]()

-

Automated process chain for the flexible production of photovoltaic modules (A3P)For the project described here, specifications are being drawn up for the automated handling of all materials for flexible module production. Concepts for handling will be created, the individual steps will be coordinated and optimised with regard to cycle times and costs. The creation of a digital twin of the process chain will then form the basis of future projects. A main focus of investigation is on the handling processes of the glass elements and the lamination foils.Team:Year: 2023Funding: EFZN

![]()

![]()

Mobile Robotics and Robot Assisted Processes

-

Handling of solar cellsThe aim of the project is the investigation of parallel robots for high speed handling operations of solar cells for industrial applications. Alternative parallel kinematic structures for the handling of solar cells are to be designed and the functional models of the CRC 562 for industrial tasks are to be investigated in terms of their suitability.Team:Year: 2011Funding: DFG

![]()

![]()

-

ProVorPlus (Functionally integrated process technology for preassembly and component manufacturing of FRP metal hybrids)In order to increase the economic potential of fiber-reinforced plastic-based lightweight construction, the production of components with component integrated hybridization is appreciated. Different materials with different properties are combined to form a single component, which enables the functionalization (mechanical, thermal and electrical) of the individual materials.Team:Year: 2015Funding: BMBF

![]()

![]()

-

Generative Manufacturing in ConstructionThe production of concrete components in the building industry has always followed the traditional manual process, in which buildings have to be built "stone by stone" and the concrete elements have to be manufactured by means of elaborate wooden formwork. Although the construction industry has powerful calculation software and high-performance concretes, the production process is complex and not automated. This is where the above-mentioned project comes in. The aim is to use a fully automated, robot-based production cell to produce generatively free formed concrete components for building construction.Team:Year: 2016Funding: MWK

![]()

![]()

-

Cable-driven orientation deviceIn the area of "cable-driven orientation devices", structural extension mechanisms (three dof) for delta-robots are being researched which are actuated by means of bowden-cables. If the motors of the extension mechanism are attached to the base frame of the robot system, the robot mass will be reduced and the mechanical stress of the structure decreases.Team:Year: 2016

![]()

![]()

-

Methods for automation of handling processes under cryogenic conditionsIn today's industry, automation is a ubiquitous factor, even in niche applications such as cryopreservation. Manual handling of biological or toxic samples is still the norm in research facilities. Such samples are preserved and stored in so-called cryobanks at temperatures ranging from -130°C to -196°C. In cryobanks commonly used today, samples are often stored and retrieved or moved by hand with bulky protective clothing. This is necessary because there is a significant risk of injury to the worker from cold burns, as well as a risk to sample integrity from damage and heating or even temperature changes. To overcome these problems, full automation at temperatures below -130 °C is desirable. As part of the DFG-funded project "Methods for the automation of handling processes under cryogenic environmental conditions", approaches for the automation of handling processes in biobanks for cryopreservation in the temperature range below -130°C are being researched at match in cooperation with the Fraunhofer Institute for Biomedical Engineering (IBMT, Sulzbach/Saar). The challenge is to ensure the functionality of the machine components (joints, sensors, energy supply, etc.) in this temperature range in order to be able to operate the biobank at a constant low temperature level. This is intended to prevent damage to the samples due to temperature fluctuations and at the same time increase the efficiency and reproducibility of the handling processes. The basis of the automation system is a parallel robot. Its structure allows the drive technology to be decoupled from the low-temperature area and placed outside, i.e. in the warm area. In order to transfer the drive motion to the end effector platform, methods for designing passive solid-state joints are being researched at match so that they can be used at the required temperatures, e.g. using a suitable temperature control concept.Team:Year: 2017Funding: DFG

![]()

![]()

-

SafeMateThe goal of the research project SafeMate is to implement collaborative assembly systems in cross-industry applications and to develop general strategies and concepts for the introduction and design of such systems. These general strategies are to be summarised in a guideline, which is intended to provide companies with guidance in the form of action and decision-making corridors when designing collaborative assembly systems.Team:Year: 2017Funding: BMBF

![]()

![]()

-

Adaptable and Component-Protecting Disassembly in the Regeneration PathPart of the DFG-funded Collaborative Research Centre 871 "Regeneration of Complex Capital Goods" is a "component friendly and adaptable disassembly". Disassembly initiates the regeneration process of an aircraft engine. By automating the disassembly processes and identifying the process variables, it is possible to disassemble components in a way that is gentle on the components despite characteristic uncertainties.Team:Year: 2018Funding: DFG

![]()

![]()

-

Economic production of load-compatible FRP / metal compositesIn cooperation with the IFUM (Institute for Forming Technology and Forming Machines), this project aims to develop and optimize an economical production of load-bearing FRP / metal composites. Local FRP accumulations are to be arranged and fixed between two steel sheets. Subsequently, the layer structure is transferred to a two-stage press for impregnation and forming.Team:Year: 2018Funding: EFB/AiF

![]()

![]()

Precision Assembly

-

Cooling concepts based on electrocaloric materialsElectrocaloric materials belong as other caloric materials to the group of the active materials and show a temperature change under the influence of an electric field. For applications that temperature range, the exploitation of the electrocaloric effect promises great potential. This is particularly the case in systems with limited energy, for example in e-mobility.Team:Year: 2012Funding: DFG

-

Methods for automation of handling processes under cryogenic conditionsIn today's industry, automation is a ubiquitous factor, even in niche applications such as cryopreservation. Manual handling of biological or toxic samples is still the norm in research facilities. Such samples are preserved and stored in so-called cryobanks at temperatures ranging from -130°C to -196°C. In cryobanks commonly used today, samples are often stored and retrieved or moved by hand with bulky protective clothing. This is necessary because there is a significant risk of injury to the worker from cold burns, as well as a risk to sample integrity from damage and heating or even temperature changes. To overcome these problems, full automation at temperatures below -130 °C is desirable. As part of the DFG-funded project "Methods for the automation of handling processes under cryogenic environmental conditions", approaches for the automation of handling processes in biobanks for cryopreservation in the temperature range below -130°C are being researched at match in cooperation with the Fraunhofer Institute for Biomedical Engineering (IBMT, Sulzbach/Saar). The challenge is to ensure the functionality of the machine components (joints, sensors, energy supply, etc.) in this temperature range in order to be able to operate the biobank at a constant low temperature level. This is intended to prevent damage to the samples due to temperature fluctuations and at the same time increase the efficiency and reproducibility of the handling processes. The basis of the automation system is a parallel robot. Its structure allows the drive technology to be decoupled from the low-temperature area and placed outside, i.e. in the warm area. In order to transfer the drive motion to the end effector platform, methods for designing passive solid-state joints are being researched at match so that they can be used at the required temperatures, e.g. using a suitable temperature control concept.Team:Year: 2017Funding: DFG

![]()

![]()

Digital Production and Autonomous Systems

-

Cooling concepts based on electrocaloric materialsElectrocaloric materials belong as other caloric materials to the group of the active materials and show a temperature change under the influence of an electric field. For applications that temperature range, the exploitation of the electrocaloric effect promises great potential. This is particularly the case in systems with limited energy, for example in e-mobility.Team:Year: 2012Funding: DFG

-

Automated process chain for the flexible production of photovoltaic modules (A3P)For the project described here, specifications are being drawn up for the automated handling of all materials for flexible module production. Concepts for handling will be created, the individual steps will be coordinated and optimised with regard to cycle times and costs. The creation of a digital twin of the process chain will then form the basis of future projects. A main focus of investigation is on the handling processes of the glass elements and the lamination foils.Team:Year: 2023Funding: EFZN

![]()

![]()

Developing and Optimising of Handling and Assembly Processes (until 2024)

-

Handling of solar cellsThe aim of the project is the investigation of parallel robots for high speed handling operations of solar cells for industrial applications. Alternative parallel kinematic structures for the handling of solar cells are to be designed and the functional models of the CRC 562 for industrial tasks are to be investigated in terms of their suitability.Team:Year: 2011Funding: DFG

![]()

![]()

-

Methods for automation of handling processes under cryogenic conditionsIn today's industry, automation is a ubiquitous factor, even in niche applications such as cryopreservation. Manual handling of biological or toxic samples is still the norm in research facilities. Such samples are preserved and stored in so-called cryobanks at temperatures ranging from -130°C to -196°C. In cryobanks commonly used today, samples are often stored and retrieved or moved by hand with bulky protective clothing. This is necessary because there is a significant risk of injury to the worker from cold burns, as well as a risk to sample integrity from damage and heating or even temperature changes. To overcome these problems, full automation at temperatures below -130 °C is desirable. As part of the DFG-funded project "Methods for the automation of handling processes under cryogenic environmental conditions", approaches for the automation of handling processes in biobanks for cryopreservation in the temperature range below -130°C are being researched at match in cooperation with the Fraunhofer Institute for Biomedical Engineering (IBMT, Sulzbach/Saar). The challenge is to ensure the functionality of the machine components (joints, sensors, energy supply, etc.) in this temperature range in order to be able to operate the biobank at a constant low temperature level. This is intended to prevent damage to the samples due to temperature fluctuations and at the same time increase the efficiency and reproducibility of the handling processes. The basis of the automation system is a parallel robot. Its structure allows the drive technology to be decoupled from the low-temperature area and placed outside, i.e. in the warm area. In order to transfer the drive motion to the end effector platform, methods for designing passive solid-state joints are being researched at match so that they can be used at the required temperatures, e.g. using a suitable temperature control concept.Team:Year: 2017Funding: DFG

![]()

![]()

-

Adaptable and Component-Protecting Disassembly in the Regeneration PathPart of the DFG-funded Collaborative Research Centre 871 "Regeneration of Complex Capital Goods" is a "component friendly and adaptable disassembly". Disassembly initiates the regeneration process of an aircraft engine. By automating the disassembly processes and identifying the process variables, it is possible to disassemble components in a way that is gentle on the components despite characteristic uncertainties.Team:Year: 2018Funding: DFG

![]()

![]()

-

Automated process chain for the flexible production of photovoltaic modules (A3P)For the project described here, specifications are being drawn up for the automated handling of all materials for flexible module production. Concepts for handling will be created, the individual steps will be coordinated and optimised with regard to cycle times and costs. The creation of a digital twin of the process chain will then form the basis of future projects. A main focus of investigation is on the handling processes of the glass elements and the lamination foils.Team:Year: 2023Funding: EFZN

![]()

![]()

Machine Concepts and System Integration (until 2024)

-

Active tool holding deviceThe research aim is to increase the productivity of machine tools with rotating tool holding devices by actively influencing the machine structure. The limiting factor for the performance of a machine tool is the dynamic and static behaviour of the structure. If machine tools are operated near their limits, undesired machine vibrations may occur. As a result, either the machining of the workpieces cannot be completed or the selected parameter values do not fully exploit the machine's performance.Team:Year: 2011Funding: DFG

![]()

![]()

-

Cooling concepts based on electrocaloric materialsElectrocaloric materials belong as other caloric materials to the group of the active materials and show a temperature change under the influence of an electric field. For applications that temperature range, the exploitation of the electrocaloric effect promises great potential. This is particularly the case in systems with limited energy, for example in e-mobility.Team:Year: 2012Funding: DFG

-

iAeroIn cooperation with the IFA (Institute of Production Systems and Logistics), an aerodynamic feeding system is to be developed further in this project, so that parts can be fed flexibly and in large quantities into a subsequent process. Based on the geometric data of the parts and a simulation model of the orientation process, the system should independently identify, adjust and apply the optimal setting parameters.Team:Year: 2017Funding: DFG

![]()

![]()

Robot aided Assembly and Handling Processes (until 2024)

-

3C-PKMThe aim of the project "Development of a parallel kinematic structure for the 3C application field" is to analyse and further develop the kinematics of an ABB Flexpicker in order to meet the requirements of handling and assembly tasks in electronics assembly. To this end, the workflow of a possible development process is worked out and relevant boundary conditions and target parameters are identified.Team:Year: 2012Funding: DFG

![]()

![]()

-

ProVorPlus (Functionally integrated process technology for preassembly and component manufacturing of FRP metal hybrids)In order to increase the economic potential of fiber-reinforced plastic-based lightweight construction, the production of components with component integrated hybridization is appreciated. Different materials with different properties are combined to form a single component, which enables the functionalization (mechanical, thermal and electrical) of the individual materials.Team:Year: 2015Funding: BMBF

![]()

![]()

-

Generative Manufacturing in ConstructionThe production of concrete components in the building industry has always followed the traditional manual process, in which buildings have to be built "stone by stone" and the concrete elements have to be manufactured by means of elaborate wooden formwork. Although the construction industry has powerful calculation software and high-performance concretes, the production process is complex and not automated. This is where the above-mentioned project comes in. The aim is to use a fully automated, robot-based production cell to produce generatively free formed concrete components for building construction.Team:Year: 2016Funding: MWK

![]()

![]()

-

Cable-driven orientation deviceIn the area of "cable-driven orientation devices", structural extension mechanisms (three dof) for delta-robots are being researched which are actuated by means of bowden-cables. If the motors of the extension mechanism are attached to the base frame of the robot system, the robot mass will be reduced and the mechanical stress of the structure decreases.Team:Year: 2016

![]()

![]()

-

Methods for automation of handling processes under cryogenic conditionsIn today's industry, automation is a ubiquitous factor, even in niche applications such as cryopreservation. Manual handling of biological or toxic samples is still the norm in research facilities. Such samples are preserved and stored in so-called cryobanks at temperatures ranging from -130°C to -196°C. In cryobanks commonly used today, samples are often stored and retrieved or moved by hand with bulky protective clothing. This is necessary because there is a significant risk of injury to the worker from cold burns, as well as a risk to sample integrity from damage and heating or even temperature changes. To overcome these problems, full automation at temperatures below -130 °C is desirable. As part of the DFG-funded project "Methods for the automation of handling processes under cryogenic environmental conditions", approaches for the automation of handling processes in biobanks for cryopreservation in the temperature range below -130°C are being researched at match in cooperation with the Fraunhofer Institute for Biomedical Engineering (IBMT, Sulzbach/Saar). The challenge is to ensure the functionality of the machine components (joints, sensors, energy supply, etc.) in this temperature range in order to be able to operate the biobank at a constant low temperature level. This is intended to prevent damage to the samples due to temperature fluctuations and at the same time increase the efficiency and reproducibility of the handling processes. The basis of the automation system is a parallel robot. Its structure allows the drive technology to be decoupled from the low-temperature area and placed outside, i.e. in the warm area. In order to transfer the drive motion to the end effector platform, methods for designing passive solid-state joints are being researched at match so that they can be used at the required temperatures, e.g. using a suitable temperature control concept.Team:Year: 2017Funding: DFG

![]()

![]()

-

SafeMateThe goal of the research project SafeMate is to implement collaborative assembly systems in cross-industry applications and to develop general strategies and concepts for the introduction and design of such systems. These general strategies are to be summarised in a guideline, which is intended to provide companies with guidance in the form of action and decision-making corridors when designing collaborative assembly systems.Team:Year: 2017Funding: BMBF

![]()

![]()

-

Economic production of load-compatible FRP / metal compositesIn cooperation with the IFUM (Institute for Forming Technology and Forming Machines), this project aims to develop and optimize an economical production of load-bearing FRP / metal composites. Local FRP accumulations are to be arranged and fixed between two steel sheets. Subsequently, the layer structure is transferred to a two-stage press for impregnation and forming.Team:Year: 2018Funding: EFB/AiF

![]()

![]()