Handling of Hot-Forged Hybrid Components in the Process of Tailored Forming

| E-Mail: | ince@match.uni-hannover.de |

| Team: | Caner Ince |

| Year: | 2019 |

| Funding: | DFG |

The Collaborative Research Center (CRC) 1153 "Tailored Forming" aims to develop the potential for hybrid solid components based on a novel process chain and to develop the necessary manufacturing processes. In contrast to existing manufacturing and production processes for hybrid components, where the joining process takes place only during forming or at the end of the production chain, the CRC uses tailored semi-finished products that are joined before the forming process. In this way, components can be produced that meet the necessary requirement profiles of the different structural and functional areas in the component much better than components made of mono-materials. In addition, by combining different materials within a component with the same or improved performance, either the weight of the component can be reduced through the local use of lightweight materials or the cost of the component can be reduced by combining low-cost alloys with high-grade alloys.

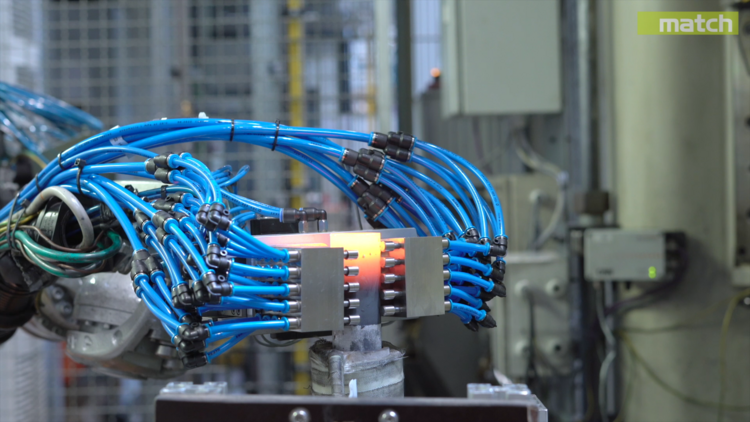

The handling of Tailored Forming components along the process chain from blank to finished part places a wide variety of demands on gripping technology. The parts to be handled vary greatly in shape and weight and reach temperatures of up to 1250 °C during handling. Some process steps have additional requirements for the positioning or temperature control of the parts. Grippers that meet all these requirements do not currently exist.

The aim of subproject C7 is therefore to provide, validate and evaluate functional modules for the development of shape-variable gripper systems for the safe and precise handling of tailored forming components with different geometries and surface temperatures of more than 300°C up to 1250°C, taking into account additional process requirements (e.g. cooling of the components in the gripper).