Adaptable and Component-Protecting Disassembly in the Regeneration Path

| E-Mail: | bluemel@match.uni-hannover.de |

| Team: | Richard Blümel |

| Year: | 2018 |

| Funding: | DFG |

| Is Finished: | yes |

Motivation and Objective

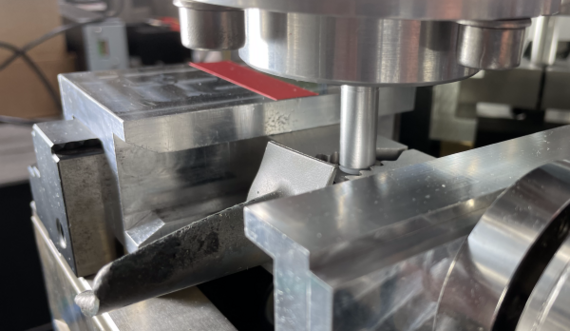

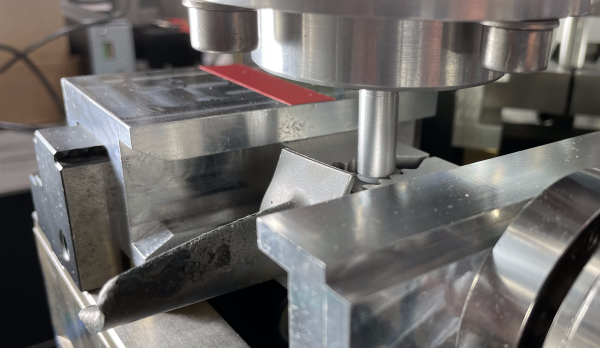

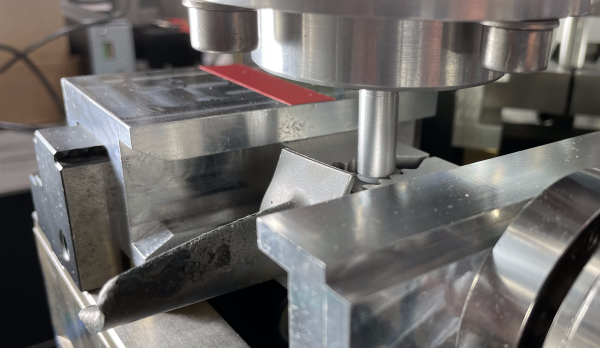

An essential difference between new production and the regeneration of complex capital goods is disassembly. In order not to cause additional damage to the components, which would lead to higher repair costs or, in the worst case, to scrap, disassembly must be as gentle as possible on the components. An adaptive disassembly process should achieve maximum component protection, despite an unknown product condition. In contrast to assembly, where joining tolerances are known and joining forces can therefore be estimated, it is not possible to specify the required disassembly forces in disassembly due to product stresses during operation, such as thermal or mechanical loads. The high-pressure turbine considered in the research project, in particular, is subjected to very high stresses during operation so that after operation the connection of the turbine blades in the turbine disk is solidified to an unknown high degree. For disassembly planning, unknown disassembly forces mean that disassembly times and tool dimensioning can only be roughly estimated and are only determined in the process or even remain undefined. The aim of the subproject is therefore to achieve maximum component protection by means of an adaptive disassembly process in the case of an unknown product state.

Insights gained and outlook

Based on experimental and numerical investigations, a method for determining the disassembly forces is developed. From this, disassembly planning parameters such as tool forces or disassembly duration can be derived. In a learning process, disassembly forces and curves are recorded and assigned to product properties such as operating hours, geometry properties and operational loads. In addition, based on mechanical modelling of the assembly joint, the process parameters of disassembly are decoupled from geometric parameters and design properties. This makes it possible to transfer disassembly planning parameters from an already known blade type to further product variants to enable flexible and efficient disassembly planning.

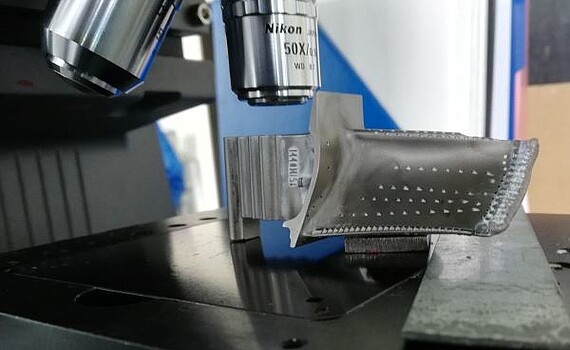

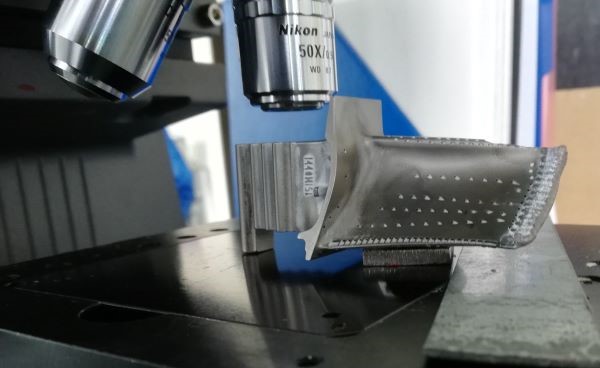

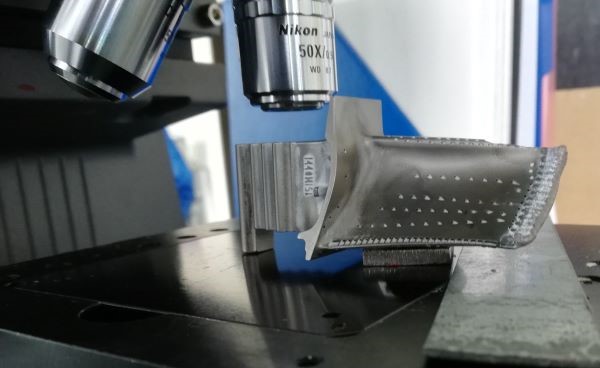

A piezo stack actuator is used as a disassembly process to generate targeted impacts on the solidified joining partners and detach the joint. In this way, an automated and thus reproducible disassembly process can be implemented from the previously uncontrolled manual disassembly using a hammer. The impact amplitudes and impact frequencies as controlled variables are implemented from the disassembly planning as feedforward control. To monitor component protection, the turbine blades are then examined to evaluate the influence of the disassembly parameters, such as force and speed of the disassembly tool or frequency and amplitude of the micro impacts, on the material.

With the conceptual implementation of a disassembly workstation, including secondary processes such as handling, an entire disassembly process is illustrated. This concept has already been integrated into the system demonstrator of CRC 871 as the process cell "component-friendly disassembly".