in HIS-LSF

Course Type | Lecture + Excercise Course |

| Level | Main Studies / Master |

| Semester | Summer Semester |

| Creditpoints | 5 CP |

Course Objectives

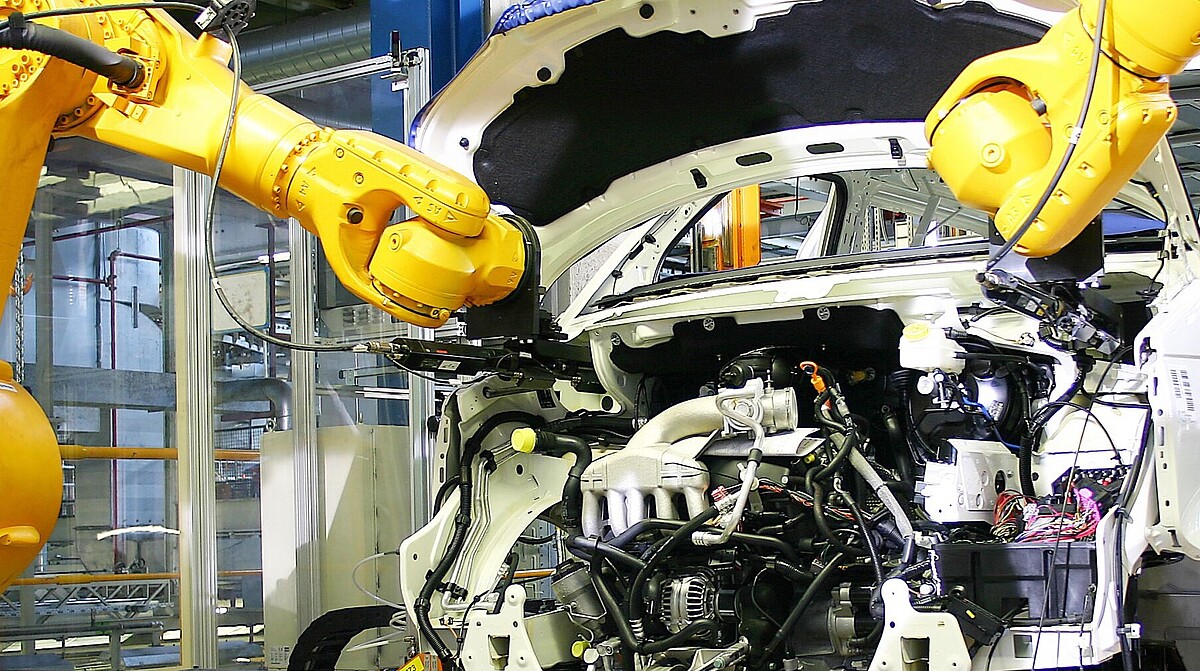

The lecture Applied Automation and Assembly provides a holistic overview of the technical, economic and ecological challenges of innovative assembly tasks using numerous practical examples. In addition to the area of engine and gearbox assembly, the applications covered include, in particular, the assembly of battery cells and packs as well as the assembly of fuel cells. Among other topics, the use of robotics and automation technology for production optimization is also addressed.

Upon successful completion, students will be able to:

- Plan and design highly efficient assembly systems with the aid of robotics and automation technology.

- Describe the challenges of assembling alternative vehicle powertrains such as electric motors and fuel cells.

- Understand the variables influencing assembly planning and identify the parameters relevant to the specific assembly task.

- Implement integrated quality assurance in assembly by selecting intelligent procedures for measurement, inspection and testing.

- Apply the basics of project management according to PMI to real-life examples.

Course Contents

The basics of project management according to PMI are taught; they support the structured handling of complex assembly tasks. The lecture is complemented by excursions to suppliers and operators of assembly systems of various types.

Module contents:

- Assembly and automation technology for large-scale industrial production of different drive systems (combustion engines, electric motors, battery cells, fuel cells)

- Automation of assembly processes (manual, hybrid, automated workstations; feeding technology; industrial robots)

- Planning, design and execution of complex assembly and transfer systems using practical examples

- Measurement, inspection and testing within industrial assembly systems for series production

- Applied project management based on real assembly processes in a large-scale industrial environment

- Excursions to two to three different companies (e.g. Thyssen Krupp Automation Engineering, Bosch Rexroth, VW Nutzfahrzeuge)

Information: The lecture is held in German. Maximum of 25 participants.

Exam Information and Registration

Your Professor